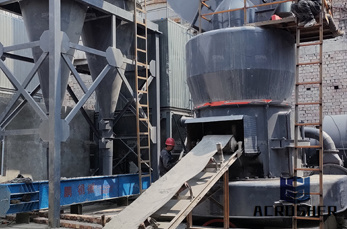

installation of ball mill

Ceramic Installation Ceramic Linings Ball Mill RepairAB Ceramics. AB Ceramics is a ceramics supplier located in Leesville, SC that sells ceramic products and handles ball mill repair, refractory, and ceramic installation.

WhatsApp)

WhatsApp)

Ceramic Installation Ceramic Linings Ball Mill RepairAB Ceramics. AB Ceramics is a ceramics supplier located in Leesville, SC that sells ceramic products and handles ball mill repair, refractory, and ceramic installation.

Jul 20, 2019· Ball mill installation is a must step before it is put into production, which will affect the subsequent use of the ball mill, and even affect the production volume, crushing rate, service life, etc., so the importance of ball mill installation is selfevident. In addition, the choice of grinding medium is .

Ball mill and rod mill are widely used in grinding link in mineral processing. They have different advantages when they process ores. The first step of using them is to know how to install them.

Installation Procedure Of Ball Mill Calcite Deep Processing Plant in Belgium Calcite deep processing production line in Belgium is composed of PE250×400 jaw crusher, electrovibrating feeder, HXM1021 micro powder mill, hoister, electrical cabinet, packing machine and pulse dust collector.

Ball Mill Working Flow Chat, Ball Mill Instruction Manual. Ball Mill Instruction Manual. The quality of ball mil installation is the key to whether the ball mill work normally.

The inner surface of the ball mill cylinder is generally equipped with various shapes of liner. Liner is the main vulnerable part of ball mill, and its use cost is about 2% ≤ 3% of the product price. The performance and service life ... 3 functions, 8 categories and 10 installation requirements of ball mill .

The E max is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time. faster and finer grinding than any other ball mill; speed of 2000 min1 allow for ultrafast pulverization of the sample

large ball mill installation offers 536 large cement mill grinding balls products. About 80% of these are cast amp; forged, 1% are ceramics, and 1% are abrasives. Get Quote. Ball Mill Maintenance Installation Procedure 911 Metallurgist.

Ball mill . A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing ... Large to mediumsized ball mills are mechanically rotated on their axis, but small ones normally co...

Ball mill installation is a link that must be experienced before the ball mill is put into operation. The installation will affect the subsequent use of the ball mill, and even affect the production, crushing rate, service life and so on, so the importance of ball mill installation is selfevident.

The installation of the ball mill is the link that the ball mill must go through before it goes into production. The quality of the installation will affect the subsequent use of the ball mill, and even affect the production, crushing rate, service life, etc., so the importance of the installation of the ball mill .

grinding mills are available at a low total cost of ownership due to low installation and operating costs, as well as simple maintenance. We can help you determine the optimum setup for your needs to maximize the profitability of your operation. Support from ''s grinding experts. Every mining operation has a unique grinding process.

Ball Mill Installation Manual Pdf Free Owners Manual PDF. ball mill installation manual pdf pdf download installation manual with drawings and spare parts, Ball mill Wikipedia The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates ...

Installation Of Grinding Mill Cement Grinding Vertical Roller Mills Versus Ball Mills. grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system.

Figure 5. High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation.

Overflow ball mill handbookinstallation and maintenance. Ball mills are the main machines in the grinding process. Mineral processing experts will choose different ball mills according to the different properties of ores, such as particle size, capacity. ...

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

Installation, Operation and Maintenance of Airflex® Model VC Grinding Mill Clutches Forward this manual to the person responsible for Installation, Operation and Maintenance of the product described herein. Without access to this information, faulty Installation, Operation or Maintenance may result in personal injury or equipment damage.

Ceramic Installation Ceramic Linings Ball Mill RepairAB Ceramics. AB Ceramics is a ceramics supplier located in Leesville, SC that sells ceramic products and handles ball mill repair, refractory, and ceramic installation. Read More. Ball Mill Installation Update Cleveland Mining.

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications.

The installation quality of the ball mill is the key to ensure the normal operation of the mill. The installation methods and order of various types of ball mills are approximately the same. Here is the correct installation steps.

BallMill Base with Ventilated MotorCover Installed BallMill Base with Ventilated MotorCover Removed The BallMill Drive System Looking inside the mill''s motor compartment, you can now see the motor, with a small fan and pulley on its shaft. That small pulley is connected by a drive belt to a large pulley which is mounted on the unit''s drive ...

the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure Ad this can be used to establish the essential features of a model for mill .

WhatsApp)

WhatsApp)