LOESCHE Compact Cement Grinding Plant (CCG Plant) YouTube

Mar 02, 2017· From the pioneer and pacemaker in grinding. The intelligent concept of LOESCHE''s CCG Plant enhances your flexibility during operation. You .

WhatsApp)

WhatsApp)

Mar 02, 2017· From the pioneer and pacemaker in grinding. The intelligent concept of LOESCHE''s CCG Plant enhances your flexibility during operation. You .

THE CEMENT MANUFACTURING PROCESS quarry raw grinding and burning grinding, storage, packing, dispatch HOW TO USE THIS PRESENTATION : > once the animation has finished, click anywhere on the screen to move on > click on « next » to see the next stage of the cement manufacturing process Click here to start THE CEMENT MANUFACTURING PROCESS 1.

ppt of grinding of cement presentation of cement grinding ppt of grinding of cement ititalcher. ppt on ball mill grinding media in cement industry, Lecture 2 SlideShe Jan 23, 2011, Lecture 2 Presentation Transcript ProfDrSal, The grinding in ball mill is therefore caused due to:, 2By impact due . Contact Supplier

A grinding aid is a specialty chemical agent used to make it easier to grind and mix cement. It has been traditionally used to improve the efficiency of the cement molturation process, one of the most energy consuming processes in cement production (60 70% of the total electricity consumed in a cement plant). – A free PowerPoint PPT presentation (displayed as a Flash slide show) on ...

Mar 09, 2014· MANUFACTURING OF CEMENT 21 November 2015 Prof. Dr. Harraz Presentation Cement 11 1) Quarry 2) Raw Material 3) Mixing and crushing of raw materials: a) Dry process b) Wet process 4) Burning 5) Grinding 6) Storage 7) Packing 8) Dispatch 12. Step in the Manufacture of Portland Cement 1.

This report focuses on the Cement Grinding Aids in Global market, especially in North America, Europe and AsiaPacific, South America, Middle East and Africa – A free PowerPoint PPT presentation (displayed as a Flash slide show) on id: 888250MjFkN

cement grinding mill ppt Effect of grinding aids on closed circuit cement grinding As introduced before, grinding aids are sprayed in the mill, or added on the clinker, with dosages usually ranging from 100200 g up to 23 kg per ton of cement.

slide 2: Actually specialists have experienced good trouble to be able to end polished concrete floors and benchtops to the sides and edges and different small places since the various tools so far have all been circular grinding wheels different compared to the really gradual and boring give polishing blocks.

Concrete Grinding and Polishing Grinding can also be used to remove other coatings and unwanted materials from concrete such as: epoxy, mastic glue, and thinset. Concrete grinding and sealing is a great way to achieve a modern look inside a home.

AIR POLLUTION CONTROL TECHNIQUES FOR THE CEMENT MANUFACTURING INDUSTRY: A CASE STUDY FOR ZIMBABWE D. Zimwara1, L. Mugwagwa1, ... grinding and homogenization of raw materials, the process of calcination is ... Cement Grinding This stage is also known as finish milling. Here the clinker is ground with other materials

Dec 20, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Aug 16, 2015· presentation on ultratech cement limited 1. !!JAI GANESHAYE NAM!! 2. WHAT IS CEMENT ??? A powdery substance made by calcining lime and clay, mixed with water to form mortar or mixed with sand, gravel, and water to make concrete.

Oct 10, 2015· Since we could end up wasting our time and budget. For this reason I recommend, my list of "The most important books of the Cement Industry": Cement .

Mar 29, 2013· The first cement unit was set up at Porbandar in 1914 with acapacity of 1,000 tones per annum. The Aditya Birla Group is the 10th largest cement producer in the world the 4th largest in Asia. UltraTech Cement Limited It is Indias 2 nd biggest cement company and India''s largest exporter of cement clinker based in Mumbai, India . O P ...

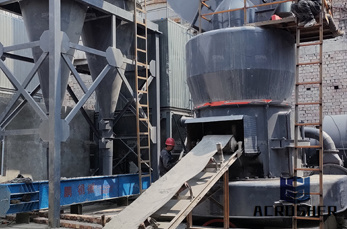

• Grinding pressure control for expansion of the mill control range from 20 to ; • Grinding table speed control with frequency converter. Loesche designs, plans and constructs everything from individual machines to turnkey drygrinding installations for all solid fuels. Loesche is certified in accordance with EN ISO 9001, and

Cement Grinding Mill authorSTREAM Presentation. Summary : Summary Material level Material level = ball level over the entire compartment Ball charge classification : progressive decrease of the ball size in C2 Diaphragm slots : first compartment slots: 6mm to 8mm second compartment outlet slots larger by at least 2mm than those of first compartment Ventilation screens they have to have the ...

Cement is a finely ground, nonmetallic, inorganic powder when mixed ... Also removes substances that adsorb to the dust particles, such as dioxins and metals. ... – A free PowerPoint PPT presentation (displayed as a Flash slide show) on id: ee7a2MTA0Y

Presentation On Optimization Of Cement Ball Mill Inlet. 201836according to the need of customers, ball mill can be either wet or dry designsall mills have been designed in standard sizes of the final products between 04 mm and 0mm in diameterpplicationhe ball mill is key equipment in grinding industry, especially in mineral ore dressing plants.

The Cement Grinding Office. Our reference list A series of real examples are exposed and interpreted. ... Tromp curve Interpretation: New presentation on power formulas with analysis and comparisons is now available (7 formulas are analyzed). Looking for a partnership in order to organize training seminars. If you are interested, click

World of Concrete is the ONLY annual international event dedicated to the commercial concrete and masonry construction industries. Featuring a worldclass education program, indoor and outdoor exhibits, demonstrations and competitions, leading suppliers showcasing new .

raw materials, fuels finished cement; o Finished grinding may consume 25 – 50 kWh/t cement, depending on the feed material grindability, additives used, plant design especially the required cement fineness. 1. Introduction Cement manufacture is energy intensive Cement grinding is the single biggest consumer of electricity in the

Posts Related to presentation of cement grinding » ppt on cement rotary klin process slids download » history of cement industry ppt presentation. Presentation on VRPM An Energy Efficient . Presentation on VRPM – An Energy Efficient Grinding System for Cement Plants Case Study of M/s Mangalam Cement Kota, Rajasthan.

The "Mill audit expert" software, also called MAE, is used to evaluate a cement ball mill and its separator. By completing only the "Fill the form" sheet, the other sheets of the program will be automatically calculated. Last but not least, all calculations will automatically generate a complete report on the situation of the grinding ...

grinding conditions associated with fine grinding of cement clinker and related products, enabling a high grinding efficiency and stable operation. Figure 3: H However, despite a generally good performance of vertical roller mills used for grinding of cement and related products the vertical roller mill is still inferior to the ball

WhatsApp)

WhatsApp)