Cement mill: lubrication system Dropsa

Cement mill: Dropsa studied a grease lubrication system that is sprayed on the teeths guaranteeing width cover of the gear...

WhatsApp)

WhatsApp)

Cement mill: Dropsa studied a grease lubrication system that is sprayed on the teeths guaranteeing width cover of the gear...

Advantageds of Girth gear lubrication system for Cement Ball Mill, rotary kiln: newtype unilateral singledrive doublesliding shoe bearing ball mill designed by our company adopts newtype shoemounted structure, with such advantages as excellent lubrication effect, light weight, easy replacement and convenient maintenance.

Lubrication oil for cement crusher equipment. For easy of Operation Maintenance all Crusher Lubrication System include their own monitoring devices SIGHT GLASSES or VIEW PORTS in the reservoir for oil level FLOW METERS in the oil lines and or VISUAL ACCESS to the discharge point of the oil circuit This is to allow the operator to gauge the oil flow visually And finally as mentioned before .

Dec 29, 2011· Cement Plant LubricationA brief on typical equipment and lubricantsCement is manufactured by either a Wet process or Dry process. In the wet process, water is addedand resultant slurry is transported through "closed conveyers" to the to a Lubrication survey, we can breakdown the lubrication at Cement Plants into 5 segments. i.

Cement mill equipment must withstand high vibration, shock loads, slow speeds and a high concentration of particulates. All of which means that contamination, loss of lubricant and even improper mounting techniques can all lead to failures for pinions or trunnions. ... Dualline lubrication systems . For oil, semifluid grease and grease up to ...

Shaan Lube Equipment Pvt Ltd is India''s leading provider of oil, grease and coolant lubrication systems to Steel, Paper, Cement, Aluminum and other heavy engineering industries. We design, build, erect, commission and maintain lubrication systems at a competitive price without compromising the quality so that we maintain a long lasting ...

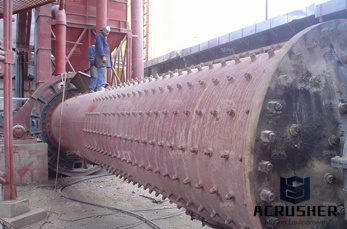

The cement mills are subjected to the wear mainly on the external gear or where the motor matches the main cement gear cylinder. The open gear is subjected to the highpower and the dust environment. This two factor can decrease the lifetime of powered pinion.

Lubrication System for Cement Industry Cement Mill ... Manufacturer of Lubrication System for Cement Industry Cement Mill Centralized Grease Lubrication System, Conveyor Centralized Lubrication System, Cement Klin Centralized Lubrication System and Spray Grease Pumps offered by Rikkon Lubes Private Limited, Chennai, Tamil Nadu.

Find Mill Lubrication Systems related suppliers, manufacturers, products and specifications on GlobalSpec a trusted source of Mill Lubrication Systems information. ... Central lubricating system is standard on all machines Automatic reversal if knives encounter large or tough steel cement parts Intelligent shredding routines ... these kinds ...

SKF solutions for cement mills SKF selfaligning bearings system A proven solution for shafts prone to misalignment SKF SNL/SAF housings ... SKF DuoFlex, dualline lubrication systems A multipoint lubrication solution for long distances and harsh conditions

Oil Lubrication Systems, Oil Lubrication System For .. Some of the products sold by the company in the category Oil Lubrication Systems are Oil Lubrication System For Bearings, Oil Lubrication System For Cement Mill.

Cenlub Systems is clearly one of the Leading Brands in Sugar Mill Lubrication. With presence in over 100 Sugar Mills and OEMs like supplies to ISGEC Thompson and ThyssenKrupp etc. Cenlub Systems is a well trusted Brand in the Sugar Mill Industry.

Large open gears on grinding and pulverizing mills present significant lubrication challenges. These challenges are due to the highload, heavyshock nature of the application and constant exposure to harsh environmental conditions, such as cement, limestone, coal or silica dust.

cement mill bearings lubrication system dietisthoofddorp. lubrication system in cement mill Grinding Mill China. Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Jan 04, 2013· Lubrication Engineers'' Pyroshield® 9011 use, in cement mill open gears. Performance results from a Lafarge cement plant in Greece.

Cement Mill Lubrication System. System used for the grinding of raw material, clinker and additives in a cement plant, as lubrication system adapted to every .

A cement mill in the Dominican Republic was experiencing availability problems with its clinker cooler. The cooler''s poor lubrication system did not cover all the necessary lubrication points, leading maintenance staff to overlubricate bearings.

Global leader in the supply of industrial lubrication products and systems

On a 11''6" x 22''0" Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill. System monitors including pressure switches and flow monitors are provided, along with temperature sensors that monitor ...

Cement Industry Lubrication Equipment Lubrication System For Gear Motor And Cement Mill Roller Grate Cooler, Find Complete Details about Cement Industry Lubrication Equipment Lubrication System For Gear Motor And Cement Mill Roller Grate Cooler,Cement Machinery Lubrication System,Ball Mill Lubrication System,Lubrication System Hydraulic Cylinder from Other Machinery .

Cement Industry Lubrication Equipment Lubrication System For Gear Motor Cement Mill Roller Grate Cooler Thrust Roller Pulverizer, Find Complete Details about Cement Industry Lubrication Equipment Lubrication System For Gear Motor Cement Mill Roller Grate Cooler Thrust Roller Pulverizer,Cement Machinery Lubrication System,Ball Mill Lubrication System,Lubrication System Hydraulic .

Cone crusher due to longterm operation, easy to appear bad lubrication device, it is often the case of the bearing bearing ablative, and even may lead to the bearing bearing cracks and loose bearing daily production, what is the problem of the main lubrication system of .

A cement mill in the Dominican Republic was experiencing availability problems with its clinker cooler. The cooler''s poor lubrication system did not cover all the necessary lubrication points, leading maintenance staff to overlubricate bearings.

Lubriion System Of Grinding Loeshe Mill In Cement Lubriion system of grinding loeshe mill in cement plant. lubriion system of atox raw mill power mining veyors, various gear units for mills, and maintenance systems for all types of plant maag gear unitsatox bevel . chat now lubriion system in cement mill sscollegein. Read More

WhatsApp)

WhatsApp)