Hammer Mill for grinding grain, spices, herbs

The Hammer Mill is the most versatile machine for grinding any material into macro fine size of 30 to 100 Mesh BSS. This machine can handle any type of material fibrous, brittle or hard.

WhatsApp)

WhatsApp)

The Hammer Mill is the most versatile machine for grinding any material into macro fine size of 30 to 100 Mesh BSS. This machine can handle any type of material fibrous, brittle or hard.

CLASSIFIER MILLING SYSTEMS ... MILLING EQUIPMENT. Air Swept Classifier Mill System. CMS Air Classifier Mills combine impact grinding and air classification in a single continuous process. Learn More. Tabletop Lab System. MILLING EQUIPMENT. Tabletop Lab System. ... Hammer Mill. The CMS Hammer Mill is a rugged highspeed industrial impact mill ...

A wide variety of maize grinding hammer mill options are available to you, There are 3,326 suppliers who sells maize grinding hammer mill on, mainly located in Asia. The top countries of suppliers are Turkey, China, from which the percentage of maize grinding hammer mill supply is 1%, 99% respectively.

Sep 20, 2019· this machine is extra blower screen type size reduction machine for grinding and crushing, application: dehydration, spices, herbs, pharmacy, chemical etc.

Type GP Hammer Mills. The Williams GP, or General Purpose Hammer Mill, is a simple, rugged answer to many small and medium capacity grinding Type GP hammer mills can be equipped with a variety of hammers—both swinging and rigid—as well as screens, breaker plates and covers to do the required work economically.

The CMS Hammer Mill is commonly used in pharmaceutical, industrial chemical, minerals, and food industries and a variety of continuous particle sizereduction applications such as cryogenic grinding of plastics and rubber and cosmetics. The Hammer Mill is easily adjustable for heatsensitive materials.

Mar 18, 2016· Here''s a video of us grinding feed with a John 2355 and a Gehl 95 Grinder Mixer. The feed is a corn based mixture that also contains dried distiller''s grains as well as several nutrients and ...

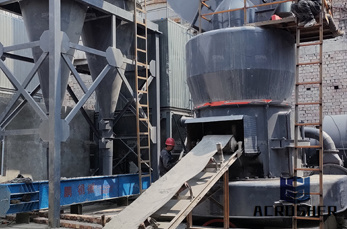

Mill Classification System. Retrofits all types of vertical airswept mills (roller mills, bowl mills, hammer mills, cagemills impactors). Easily replaces existing whizzer or cone separator. Dramatically increases production. Increased top size control. Premium Efficiency Cyclones. Maximum particulate collection.

The Hosokawa Mikro Pulverizer® Hammer and Screen Mill is one of the most versatile and durable systems for fine size reduction down to D 97 . 45 µm.. This brief video demonstration will highlight the features and operation of the Hosokawa 100 HP hammer mill (MP #4) which is used for specialty chemical applications.

The GD and 2D hammer mills are designed for the animal feed industry, to grind raw materials into small particles and meal. Both the GD and 2D hammer mill series cover capacities ranging from 5 – 100 tons per hour, dependent on type of raw material, formula and required grinding structure and can be incorporated in a pregrinding as well as a post grinding system as a complete grinding ...

Used Hammer Mills Below is ''s inventory of unused and used hammer mills. If you are looking to sell your used hammer mill submit a request online or contact Erik Eichert at

FEECO Hammer Mills. The FEECO double rotor hammer mill is a super heavyduty mill adapted to do the toughest jobs with two sets of chain / bar links. Our hammer mills reduce dry and semimoist materials with a minimum amount of fines and caking or plastering within the crusher. They are ideal for granulated and pelletized materials.

GRINDING/SHREDDING/HAMMER MILLS Scrap wood, used pallets, manufacturing offfall, waste paper plastic can bury you and cost you money. Let us show you how single shaft low RPM, high torque grinder technology can manage those waste products and instead of .

We are one of the leading manufacturer exporter of Hammer mill in Mumbai, India. We are manufacturing various types of Grinding Mills for various materials and our range of grinding mills are for Wheat, Barley, Rice, Cocoa, Coffee, Maize, Millet, Cassava, Spices, Sugar, Charcoal, Roots, Bone Antimony Ore, Coconut Fiber, Bricks, Limestone, Glass, Mica, Rock Salt, Dry Soap, Date stone, .

system, and air flow through the hammer mill ensures the required grinding results and creates optimum conditions for subsequent processes, such as mixing, pelleting, and extrusion. Thus. the grinding process is not merely a question of the hammer mill alone, but also includes everything from feed system to dischar

Hammer mill has wide application in pulverizing the raw material into powders before pelletizing in pellets making lines. Generally, hammer mill is widely used to grind branches, wood shavings, sawdust, straw, cotton and corn stalks, bagasse, alfalfa, switch grass and peanut shells, etc. GEMCO has two different kinds of hammer mills for you to choose: Small capacity hammer mill (small hammer ...

Jet mills can grind materials with low melting points effectively because these mills have intrinsic cooling due to compressed air expansion in the body of the mill. With the help of sweeping air, hammer mills may also be able to process materials with low melting points for coarse grinding .

Scrap metal recycling uses screen openings up to 3″ x 3″ in the larger primary hammer mills, and punch plate holes as small as 1/4″ in our printed circuit board (PCB) recycling hammer mills. Mt. Baker Mining and Metals'' hammer mills are industrial grade, continuous duty machines.

The dual stage EDestroyer Hammer Mill offers superfine electronic scrap grinding, under 2MM, at very high production rates. The energy resulting from the dual revolving rotors produces a suspension zone that provides additional size reduction. As a result, a finer grind is achieved in one pass through the mill.

The material remains in the hammer mill grinding chamber until particles become small enough to escape by passing through the perforated screen that covers the bottom half of the grinding chamber. Interchangeable hammer mill screens are available with hole diameters from 1/64" to 2", to allow for fine or coarse grinding of most products.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Kaps Engineers Hammer Mill Manufacturers, Hammer Crusher Manufacturers in India Exporters of hammer crusher equipment. Hammer Mills knew as Hammer Crushers. We are leading suppliers of hammer mill machine in Vadodara, Gujarat.

hammers are also common in hammer mill designs. Hammer mills are recognized as technology capable of finely grinding the greatest variety of materials [3,13] and are noted for achieving high sizereduction ratios and yielding cubicshaped particles [14,15]. Hammer mills have a wide application in biomass size reduction

Water Drop Hammer Feed Mill. Shandong Double Crane Machinery Manufacture Co., Ltd. | Feed Milling Grinding Equipment | Hammermills. Adopting international advanced technique, crush room is designed as water drop figure; With special twice crush design, the output can be increased by 25%

WhatsApp)

WhatsApp)