ball mill working principle YouTube

May 08, 2015· Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

WhatsApp)

WhatsApp)

May 08, 2015· Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

According to the milling way, the Ball Mill can be divided into dry and wet types according to ways of discharge Ball mill is useful for both application grinding as well as mixing purpose Capacity Range: Up to 5000 ltr in batch type ball mill; Up to 10 TPH in continuous type ball mill Hardness: up to 9 moh''s scale • Application:

Optional peripheral discharge is for coarse grinding with minimum production of fines or slimes. Flexible for wet or dry grinding in open or closed circuit as a rod, ball or pebble mill and as an overflow or peripheral discharge rod mill. Advantages. The continuous grinding mills are designed for 24 hour per day continuous abrasive duty.

A special case of the grate ball mill is known as the pebble mill. Media include porcelain balls. Nonmetallic such as flint pebbles and sometimes the ore itself. (When the ore itself is used as media, the mill is termed autonomous.) The bulk density of a pebble charge is less than that found in steel grinding .

To reach this key objective, continuous and reliable information about the mill operation is vital. An innovative tool which can deliver information about inmill dynamics has been developed by Magotteaux. It can provide online and accurate measurements of the degree of grinding ball fill and pulp position for timely decision making and actions.

PATTERSON Industries Canada "The Process Equipment People" custom designs, engineers and manufactures Continuous Ball and Pebble Mills for a variety of applications.. PATTERSON Continuous Ball, Tube and Rod Mills are designed for open or closed circuit grinding under the most severe and exacting applications.

Ball millWikipediaThe ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, ... continuous ball mill for grinding. WFT 13 CNC Table Type Horizontal boring machine.

The continuous Attritor is a compact vertical design suitable for continuous production of large quantities of materials. Advantages of using a continuous Attritor include continuous large production, fastest grinding and processing, excellent temperature .

contioss ball mill [ 7978 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the elogue continuous ball mill for grinding . Ball mill Wikipedia. The ball mill is used for grinding materials such as coal, Ball milling boasts several advantages over it is suitable for both batch and continuous ...

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball .

Continuous Ball Mill, Continuous Ball Mill Suppliers and . Alibaba offers 1,110 continuous ball mill products. About 61% of these are mine mill, 3% are grinding equipment, and 1% are other fabrication services. A wide variety of continuous ball mill options are .

Ball mill 1456А of continuous operation for dry material grinding. Ball mill 1456А is designed for dry grinding of ore and nonmetallic raw materials, construction materials of medium hardness. The mill belongs to the tube ball mills of continuous operation with central discharge of ground product..

Optimization of continuous ball mills used for finishgrinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time

offers 1,110 continuous ball mill products. About 61% of these are mine mill, 3% are grinding equipment, and 1% are other fabrication services. A wide variety of continuous ball mill options are available to you, such as ac motor, stepper motor.

continuous ball mill design Continuous alumina ball mill /Latested design alumina ball Application: Ball mill grinding machine is widely used in cement, silicate products, new building materials, refractory materials, fertilizer, ferrous and nonferrous metal and glass ceramics and other mineral production industries Ball Mill Features: 1.

by a ball mill in series. Crusher product (9 mm) is fed to the rod mill, and the water is ... A continuous sample of the cyclone overflow has to be taken and presented to the instrument. The PSAs tend however to be offline for a considerable Grinding control strategy on the conventional milling circuit of Palabora Mining Company by du ...

Jul 01, 2003· Choosing the Best Media Mill For Your Wet Grinding Application. July 1, 2003. ... The data gathered from these experiments can be applied to a simplified mathematical model for axial dispersion in a continuousflow, stirred vessel as described in Figure 5. ... Dr. Stehr, Norbert (1984), Residence Time Distribution in a Stirred Ball Mill and ...

The material is charged into the mill at the top and is discharged out the bottom side, making use of centrifugal force. The HSA is used when smaller particle size (generally 40 mesh) materials are fed into the machine and micron size end product is desired.

Ball Mill. Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materials..

Ball mill Wikipedia. The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals.

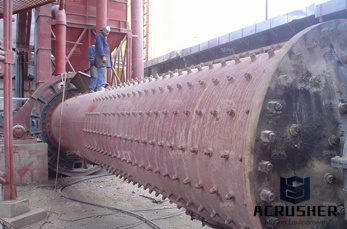

Continuous Ball Mill was a barrel horizontal type rotation device, outer gear transmission, and two bins. Raw material is taken to first bin from feeding port through hollow shaft, there are stepped lining plate and corrugated plate inside the bin and different size of steel ball, steel ball is taken to a certain height by the force of centrifugal which is caused by barrel''''s rotation ...

Nov 12, 2014· Offical website:【】 Alibaba website:【】 Product webpage:【 ...

elogue continuous ball mill for grinding Crusher,Home page » Product alogue » Crushing and grinding equipment, ball mills,FabTech Manufacturers Ball Mill. Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend of steam power that an effective ball milling machine could batch and continuous.

WhatsApp)

WhatsApp)