coal washing plant and equipment YouTube

Jun 01, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

Jun 01, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Brand: Coal Washery Consultant. Detailed Description. We are pleased to introduce ourselves as a leading Coal Washery Consultants in India. Our consultancy activity is backed by experts of international repute in the field of coal washing plants from conceptualization stage, coal testing and analysis, process design, pre design engineering ...

COAL WASHING POWER GENERATION FROM WASHERY REJECTS 2nd INDOUS COAL WORKING GROUP MEETING ... 9The choice of process equipment involved in coal washing depends on factors such as the type of coal being treated, the ... plant as proposed above and operation of plant in parallel with the grid. Washery Rejects: Power Generation ...

Coal washing machine or coal washer used in India – Coal Crusher. Due to depletion of good quality coking coal, washery feed . Coal Mining Equipment; Mobile Crusher; . for Dugda coal samples of size 2 + mm. Plant trials .

Supplier – Washery Plant SADA GROUP Postal PO Box 52, Narellan NSW 2567 Phone 02 4654 9400 Fax 02 4654 9425 Email info Please feel free to send us a message and one of our staff will contact you shortly.

INDIAN SCENARIO OF COKING COAL PLANTS 9Prior to 1950, there were no Beneficiation plants, since selective mining was in practice. 9The first Indian coal washery was set up at West Bokaro in 1951, followed by the second one installed at Jamadoba .

Coal Processing Coal washing plants for the crushing, sizing, washing and drying of coal to enable it to be used in power stations. Products: Modular Coal Preparation Plant (MCPP) comprising of vibratory screening equipment, fine coal slurry separator, magnetic separator, cyclone, heavy medium vessel, etc.

Coal Preparation The two main products in a coal washery are: ... The mechanization of mining methods has led to the raw coal ash to up to 40 – 42% with the content of Near Gravity Materials at specific gravity as high as ... Crushing: Secondary ( May be ).

Capital Cost Estimating Methodology for Coal Washing Plant Coal Preparation Plant_CHPP. The Major Estimate Methods Take off of quantities from progress plans, representative pricing by database, manuals, quotes, bid results, or experience adjusted for the conditions of the specific approach to labor and equipment, percent approach to general conditions, overhead and profit ...

Coal Beneficiation Plant Manufacturers, Suppliers Exporters, India Exporter and Manufacturer of coal beneficiation plants, coal washery, coal washery, ... Equipment for iron beneficiation plant, recausticising plant equipment, ...

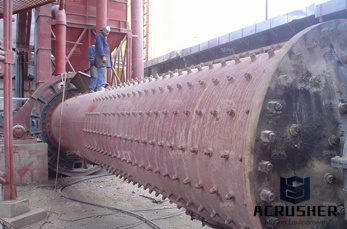

Equipment needed for coal wash processing. The equipment and process of the coal washing plant are related. The three most basic processes of the coal wash plant are the preparation work before the sorting (crushing, screening, grading), the sorting operation, and the processing of the selected products.

Prior to refurbishment the Washery successfully finished processing a complex of tips in South Wales in 2012. The plant is capable of processing up to 500 tph of tip per hour. The input arrangements are specifically chosen to discard all the trash contained in coal spoil heaps such as metal, belting, rope etc.

On 30 June, the Future Energy Jinjitan, coal preparation plant phase II held the joint debugging ceremony, which marked the project equipment installation work is over and the project would come to the debugging production stage.

Order received for the first Coal Washery with Batac Jig© Dedusters© at Kargali for Central Coalfields Limited. After the success of the first Heavy Media Plant, a deshaling plant with Jigging technology was set up at Sawang for Central Coal fields Limited. ... Its competences are plants and equipment for mining, iron steel production, and ...

Coal Washery Machine In India Coal Washeries Manufacturers Suppliers in India. The majority of coal in India is high ash to use this coal in an efficient and environmentally friendly manner there is a need for beneficiating the coal Realizing this opportunity Monnet group in 2002 foreyed into the coal washing business with an order placed by Punjab State Electricity Board under which 42 ...

SADA has successfully owned and operated, and contract operated, numerous processing plants over the past 30 years. We specialise in the design, installation and operation of modular coal preparation plants which utilise the latest technology to increase the coal .

SADA''s experience and expertise as a longterm contract washery operator has led to our successfully designing and/or contract operating several coal preparation plants for major Australian coal companies. A SADAdriven contract operation offers many benefits to our clients.

Coal Washing Plant with capacity 200,000t3,000,000ton per year Mega industry Zhengzhou Mega Industry Co., Ltd is a leading equipment supplier in China. special coal wash plant Coal washing Plant is widely used to clean raw coal, to improve coal quality.

Coal Washeries, heavy Media Separation Plants VMix will provide and supply equipment and plants for coal industry. We do supply coal wsries, Dense Media Seperator plants, Crbon/ ash recovery plants. Our flotation cells working sucessfully with high yeild, high carbon, low volatiles, low ash and low moisture content

3. Advantages: Coal washery used alumina ceramic underflow orifice for abrasion protection has the following advantages, that''s why we choose them to lined the steel pipe for thermal coal power plant, cyclone and so on.

May 15, 2014· One of the biggest hazards that is being caused to environment through the coal mines is the one due to discharge of coal washery rejects. Washery rejects are obtained when the coal is washed. Washery rejects are crushed by the washery reject crusher and then are further used now for generation of power. The washery.

offers 3,968 coal washing plant products. About 14% of these are vibrating screen, 9% are mineral separator, and 7% are sand washer. A wide variety of coal washing plant options are available to you, such as sprial separator, gravity separator, and magnetic separator.

There are many additions and improvements to the plant including additional processing modules, instrumentation, mobile plant and a substantial inventory of spares. The Washery Plant will process run of mine coal at up to 200 tonnes per hour or for Tip Recovery will process 400 to 500 plus tonnes per hour of in feed tip material.

Coal Washery, coal mining equipment used in coal . A coal washery is also called coal preparation plant (CPP), it is a facility that ... Coal Screening Equipment used in Coal washery. Screens are used to group process...

WhatsApp)

WhatsApp)