Media charge in ball mill in cement fectory. YouTube

Feb 11, 2019· The OK™ mill the most reliable and efficient mill for raw and cement grinding Duration: 2:47. FL Recommended for you

WhatsApp)

WhatsApp)

Feb 11, 2019· The OK™ mill the most reliable and efficient mill for raw and cement grinding Duration: 2:47. FL Recommended for you

Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Neural Network Modeling And Control Of Cement Mills Using. Abstract It is well known that the major cause of instability in industrial cement ball mills is the socalled plugging phenomenon A novel neural network adaptive control scheme for cement milling circuits that is able to fully prevent the mill from plugging is presented Estimates of the onestepead errors in control signals are ...

Ball Mill Motor Sizing Calculation Example. A 7 ft diameter dry grinding diaphragm mill has a 40 percent ball charge and a speed of rpm. What is the horsepower per foot of length? The mill has 2 in. thick shell liners. From graph, Fig. 3, 12, mill having 6 ft 8 in. inside diameter will have 4400 lb of balls per ft of mill .

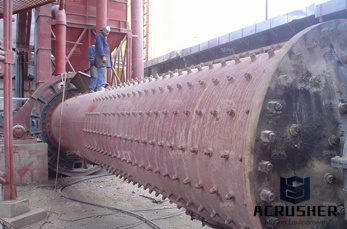

Early liner designs were ball mill for cement grinding able for large grinding media and ensures optimum lifting of the mill charge. The shell lining in the second compartment or in a onecompartment cement mill is a corrugated lining designed to obtain maximum power absorption and grinding efficiency.

Jul 18, 2016· Operation and Elements of a Closed Circuit Ball Mill System. Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding chamber.

Feb 24, 2017 Cement Mill Notebook "In Grinding Ball Charge in Mills Mill Charging Total Grinding for dry grinding of cement raw mix. get price The optimal ball diameter in a mill

ball charge for cement mills Jan 07 2015 Raw mills usually operate at 7274 critical speed and cement mills at 7476 . Calculation of the Critical Mill Speed G weight of a grinding ball in kg. w Angular velocity of the mill tube in radial/second. w = 2 (n/60) Di inside mill diameter in meter (effective mill diameter). n

Mono Chamber Raw Mill Ball Charge Design. Hi experts, I want to design a ball charge for a monochamber raw mill in a white cement plant and wanted to know your opinion about it. The raw material is preground by to a hammer crusher and after separation by a third generation separator the course material is fed to the monochamber raw mill.

We can calculate the steel charge volume of a ball or rod mill and express it as the % of the volume within the liners that is filled with grinding media. While the mill is stopped, the charge volume can be gotten by measuring the diameter inside the liners and the distance from the top of the charge to the top of the mill.

Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills.

Ball Mill Ball Charge Crusher Mills Cone Crusher Jaw, Ball chargers for cement mills crushergranite crusher this page is provide professional ball chargers for cement mills information for you we have livechat to answer you ball chargers for cement mills question here Ball Chargers For Cement Mills ... Jun 15 2018 water injection in ball mill ...

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and ...

Jul 20, 2020· P ortland cement is by far the most common type of cement in general use around the world. This articles looks at the cement manufacturing process in 4 steps. Step 1: Mining. The first step of Cement manufacturing process is to quarry the principal .

Cement Mill Ball Mill Charge Ratio taskform. Cement Ball Mill Charge Design thermoscreens. Cement Ball Mill Charge Design Previous Post Next Post Contents1 Ball charge optimization2 1 How to use the 2 Description of the main indicators used in this The residue on 2mm/4mm before partition Material filling level and ball charge Cement mill specific

Here, comminution takes place in the rolling pointcontact zone between each charge ball. An example of a two chamber ball mill is illustrated in Fig. 15. Fig. Diagram of cement ball mill. ... not least because the specific power consumption of vertical mills is about 30% less than that of ball mills and for finely ground cement ...

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball Charge

Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency:

SHAPES ON BALL MILL PERFORMANCE ... Comminution is an important process in mineral processing, power plants, cement production and pharmaceutical industries. It is costly and an inefficient process in ... Considering that worn balls in an industrial mill charge constitute about 15 to 40

Jan 07, 2015· 3. Friction between the lining and the grinding media. 4. Internal friction mill charge. Figure: Grinding media Grinding Ball Charge in Mills: According to Levenson, the optimum grinding ball charge should be r The degree of ball charge varies with in the limit of 25 and 45%. A ball charge .

May 01, 2020· The primary ball charge pattern and the design ball charge pattern that is introduced by KHD Company (Cement ball mill''s manufacture Company) are presented in Table 6. It can be observed in this table that the amount of current ball charge is about 14% less than the amount of design ball charge, so it could reduce the CBM''s efficiency.

In Order to better view check home page and Support Me. In Order to better view check home page and Support Me. Process Ball Charge Clinker Cement

cement mill ball mill charge ratio Cement mill notebook SlideShare. Jan 7, 2015 CEMENT INDUSTRY Cement Mill Notebook QATAR NATIONAL Media Grinding Ball Charge in Mills Mill Charging Tube mills have a ratio of length to diameter of [36 : 1], for ball mill .

Cement Mill Grinding Media Composition. Request for feedback for a two chamber cement mill ball charge and longitudinal sieve analysis i am looking to get feedback for the following cement mill for a white cement plant the first partment has lifting liners and the second partment has lifting at the beginning followed by classifying liner

WhatsApp)

WhatsApp)