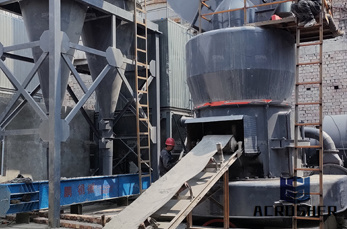

LOESCHE Compact Cement Grinding Plant (CCG Plant) YouTube

Mar 02, 2017· From the pioneer and pacemaker in grinding. The intelligent concept of LOESCHE''s CCG Plant enhances your flexibility during operation. You can process .

WhatsApp)

WhatsApp)

Mar 02, 2017· From the pioneer and pacemaker in grinding. The intelligent concept of LOESCHE''s CCG Plant enhances your flexibility during operation. You can process .

offers 11,419 cement mill grinding products. About 52% of these are mine mill, 5% are cement making machinery, and 1% are grinding equipment. A wide variety of cement mill grinding options are available to you, such as ball mill, raymond mill.

For the grinding of clinker and extenders, cement mills of the type MVR 6000 C6 are used in the cement plants and standalone grinding units of Shree Cement. The company successfully operates this type of mill at various locations. These repeat orders show the satisfaction of the customer, who has up to now ordered 34 mills from Gebr. Pfeiffer.

Cement clinker grinding plant; The ok mill the most reliable and efficient mill for raw a... Mini cement plant of 100 tons per day; Vertical cement grinding mill; Production at ramco cement plant in india; 3d presentation of a complete cement grinding plant; Mini cement plant; Jk lakshmi cement manufacturing process; Stainless steel semi ...

Cement Mill, Cement Mill Manufacturers Suppliers, Dealers. We are making and supplying of Cement Ball Mill Plant in Zhengzhou, Henan, China. Cement raw material ball mill plant for grinding grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground.

The consumption of energy by the cement grinding operation amounts to one third of the total electrical energy used for the production of cement. The optimization of this process would yield substantial benefits in terms of energy savings and capacity increase. Optimization of the Cement Ball Mill .

Likewise for coal grinding, a vertical mill is used and for the energyintensive finish grinding process, the ball mill plus roll press system is widely popular. Says Dr. Suchismita Bhattacharya, Process, Head, Penta India Cement and Minerals, ´Today the predominant factor in setting up a new plant is sustainability. Owners will want to ...

2nd hand cement grinding mill India Gulin Machinery. Popular QA for 2nd hand cement grinding mill India. Q: Why is the process of preparing food by plants called ... Get Price. used clinker grinding plant for sale india 10 may 2017. cement clinker grinding plant second hand. ... Feb 14, 2016 Cement Grinding Unit Price In India, cement clinker ...

We are the leading manufacturers of Clinker Grinding Unit in India. Product Details : ... Grey Cement for OPC, PPC and Slag Cement, White Cement: Capacity: 1 25 ton per hour capacity: The system include crushing section to milling section to cement packing section. Sr. ... Ball Mill: Grinding Mill Ball Mill Laboratory Ball Mill:

Cement Grinding Ball Mill Process At India. clinker grinding ball mill manufacturers in india Cement Ball Mill Manufacturer India. The grinding process in ball mills ... Read More. Line Crusher Cement Plant In India

offers 11,383 cement grinding mill products. About 52% of these are mine mill, 1% are grinding equipment, and 1% are flour mill. A wide variety of cement grinding mill options are available to you, such as ball mill, raymond mill.

LUM Series Cement Mills designed and produced by our factory are very suitable for crushing and grinding ceramic clay ores, and can process ceramic clay ores to the fineness required by users. Here we introduce the application of LUM series Cement Mill in ceramic clay processing.

Cement Ball Mill. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

Vertical Roller Mill Manufacturers and Suppliers In India Ashoka ... Vertical Roller Mills: Ashoka Group Manufacture all type of rolling mills and ... Vertical Roller Mills belongs to the category of grinders that are used in grinding ... in various industrial process including cement processing industry, ceramics,... Get price; Energy ...

This is achieved in a cement raw mill. The grinding process is controlled to obtain a powder with a broad particle size range, in which typically 15% by mass consists of particles below 5 μm diameter, and 5% of particles above 45 μm.

Rotary Kiln Cement Plant . The rotary kiln has an important role to play in the cement manufacturing process taking place in the cement plant. At Technomart, we specialize in manufacturing efficient and performanceoriented rotary cement kilns for successful completion of cement production.

Cement grinding process,Vertical roller mills and ball mills . Around 110 years ago a Danish engineer, M. Davidsen, patented a pioneering invention in France which involved a tube mill with a charge of steel balls or flint .

Apr 01, 2010· Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %.

This company is sixth in our list of top 10 cement companies in India. The production capacity of this company is around million tons in a year. This company currently manages around 8 integrated cement plants and around 2 grinding units.

Cement ball mill for sale in india used Manufacturer Of . Ball Mill for Cement Grinding in India . Ball Mill for Cement Grinding in India Ball mill is used for dry and wet grinding of different materials such as cement materials, cement, lime and ceramic materials SBM has continuously refined the design of its ball mills Horizontal ball mills have bee a reliable part of grinding plants Cement ...

Nov 05, 2017· re Re: Cement Grinding Aid. Yes. cement grinding aids must raise at least 10% output. Our Cement Grinding Aids dosage per ton, can ensure raise more than ≥ 10% output ( Productivity) and reduce ≥5% clink consumption.

Chanderpur Works Pvt., IndiaManufacturer and supplier of cement grinding plant like cement machine, linker grinding plant, portland cement... Get Quote; Grinding Mill Manufacturers in India, Grinding Mill Suppliers, Indian ...

Aug 30, 2012· Roller crushes the material to a fine powder and finishes the job. Raw mix is stored in a prehomogenization pile after grinding raw mix to fine powder. Cement Manufacturing Process Phase III: Preheating Raw Material. After final grinding, the material is ready to face the preheating chamber.

Cement Clinker Grinding Process. Cement grinding station is finally finished stage of cement production the formation of individual independence and cement products production units. This phase will cement clinker grinding on mixed with just the right amount of material, cement .

WhatsApp)

WhatsApp)