Cement Plants located in Malaysia The Global Cement Report

Cement Plant Location Information for Malaysia. Cement plant locations and information on Malaysia can be found below. For full access to the database, purchase The Global Cement .

WhatsApp)

WhatsApp)

Cement Plant Location Information for Malaysia. Cement plant locations and information on Malaysia can be found below. For full access to the database, purchase The Global Cement .

We are a International trader for cement and clinker, we also buy sell list selling cliker from Indonesia pmt fob fob clinker ( standby L/C or BG)We can supply any amount of Quantity ofr ...

process of cement plant malaysia. ... Barite processing plant; Basalt stone processing plant; Bauxite processing plant; ... The cement mill grinds the clinker to a fine powder. A small amount of gypsum a form of calcium sulfate is normally ground up with the clinker. The gypsum controls the setting properties of the cement when water is added.

cement clinker grinding plant used want to buy[mining plant] Cement Ball Mill Plant Malaysia Crusher,Malaysia Cement Ball mill is used for cement grinding. Cement Ball is applied for cement mill plant. In cement mining, you need to and chemical industry, cement clinker grinding. Lafarge Pasir Gudang Cement Grinding Mill Industry About

In Algeria''s cement processing industry, the clinker grinding mill refers to the grinding plant used in the grinding process of clinker grinding equipment is the most popular equipment in the, the ball mill, vertical roller mill and trapezium mill can take the role of clinker .

Aug 30, 2012· Generally cement plants are fixed where the quarry of limestone is near bye. This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing.

offers 98 cement clinker malaysia products. About 8% of these are mine mill, 7% are cement, and 1% are other drying equipment. A wide variety of cement clinker malaysia options are available to you, such as acidproof, expansive, and refractory.

Lafarge Malaysia Cement • 1,120 employees • 3 integrated cement plants • 1 clinker grinding plant • > million tonnes Malaysia is one of Lafarge''s key markets in SouthEast became a part of Lafarge in 2001 through the acquisition of Blue Circle. Industrial and sales activities in Cement, Aggregates Concrete. Lafarge Malaysia Berhad is the largest cement manufacturer ...

1Integrated Cement Plant: Or simply called Cement Plant. Both clinkerization and grinding processes take place. For the clinkerization process a cement plant has a rotary kiln. Some cement plants make clinker for its own and also for other facilities specialised in the grinding process only.

The production process of cement clinker is energyintensive and requires a large amount of fuel. Table 1 shows the increase in fuel consumption experienced by Mugher Cement plant over time. Table 1. Furnace Oil Consumption by Mugher Cement Plant, (Taddele, 2008) Year Fuel Consumed (litres) Fuel (Birr)

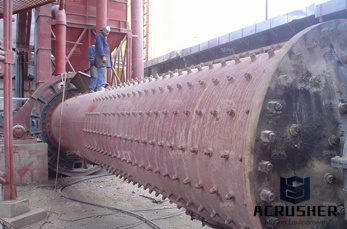

Cement Mill Overview. A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills. Cement clinker is usually ground using a cement ball mill. This is essentially a large rotating drum containing grinding media normally steel balls.

Cement is the glue that holds the concrete together, and is therefore critical for meeting society''s needs of housing and basic infrastructure. This paper deals with a case study of a reputed cement clinker processing plant, some changes in the process has been suggested, which leads to reduction in labor cost and production cost.

Getting control and measurement right at the heart of the extractive or processing operations is key to boosting profitability and maintaining reliability. Siemens can support customer needs in the mineral, aggregates and cement industries from power generation through plant automation.

May 27, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

May 27, 2019· Guangxi Guigang Cement Kiln Coprocessing solid waste project is the largest of its kind in ChinaGuangxi Guigang Cement Kiln Coprocessing solid waste project starts operating, ... New coprocessing cement plant inaugurated in China; Plant Expansions . ... Cement and clinker trade prices rise in August ; 16 August 2019 .

Designing Green Cement Plants provides the tools and techniques for designing new large cement plants that would promote sustainable growth, preserve natural resources to the maximum possible extent and make least possible additions to the Greenhouse Gases that cause global warming.

Cement Clinker Processing Plant The main raw materials used in the cement manufacturing process are limestone, clay, sand, shale and iron ore. Limestone is usually mined on site while the other minor materials may be mined either on site or in nearby quarries.

Apr 13, 2019· Shareholders: Cement Industries of Malaysia Bhd (CIMA) (United Engineers Malaysia Bhd (UEM) ) ... Maderas Keylo A Estrada Wood Processing Plant Madeiras Asorey San Miguel de Castro Sawmill Cacharado A Cañiza Sawmill Madeiras Vázquez A Bugalleira Sawmill

Apr 13, 2009· The steady growth of the cement industry in Malaysia saw the need for an Association to look after its interests. In 1965, the Cement and Concrete Association (CCA) of Malaysia came into being with 3 founding members Malayan Cement Limited (MCL), Malaya Industrial and Mining Corporation (MIMCO) and Tasek Cement Limited (TCL).

universiti putra malaysia case study on: abc cement ... Core. Aug 8, 1997 ... Location of Malaysia cement plants. Installed capacity of cement plants by company, 1996. Clinker production capacity by company, 1996. Read More

Cement Processing Plant Malaysia Feed Back Concrete Wikipedia Concrete is a composite material composed of coarse aggregate bonded together with a fluid cement . live chat; malaysia used cement mill plant for barite dolomite.

After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone. Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects.

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

Clinker, which is produced by sintering limestone, is the core ingredient in producing cement. Shun Shing Group, one of the largest independent traders of clinker in the Asia Pacific region, supplies over five million tons of clinker annually.

WhatsApp)

WhatsApp)