Used Grindingballs For Sale Grinding Mills, Crushers ...

Inventory ID: 6CAP02. 75 Units/Barrels Used Grinding Balls, ranging in size from approximately 1" to 4" (Note: A Barrel is approximately 1Ton)

WhatsApp)

WhatsApp)

Inventory ID: 6CAP02. 75 Units/Barrels Used Grinding Balls, ranging in size from approximately 1" to 4" (Note: A Barrel is approximately 1Ton)

Grinding in small plants, as in larger installations, has proven to be the most costly of all unit operations from both capital and operating standpoints. Therefore, grinding deserves the most scrutiny of all operations during the design procedure. A recent survey by a major grinding mill manufacturer reveals that more than 80 autogenous or semiautogenous mills having .

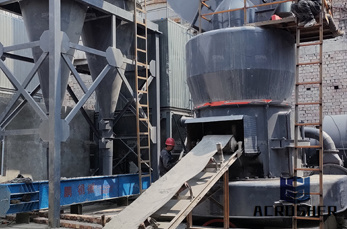

Compared with common grinding mills, the capacity is 30% higher than that of similar products and the power consumption is 30%60% lower than that of ball mill. Better Quality Its unique way of material handling can effectively control the particle, chemical composition and iron content of kaolin products, ensuring the purity and whiteness of ...

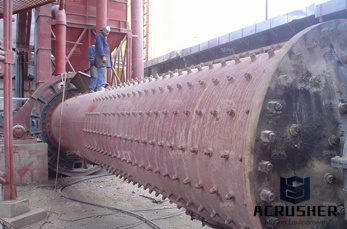

It is primarily used in the gold, copper and platinum industries as well as in the lead, zinc, silver, and nickel industries. Autogenous (AG) grinding mills involve no grinding media as the ore itself acts as the grinding media. Our ball mills are the most robust design in the industry, available with either geared or gearless drive arrangements.

Inventory ID: 6KTA01. 17 Units Barrels of USED Steel Grinding Balls, approximately 3/4" 1" mixed barrels

In mining industry, there are many types of ultra fine grinding mill like Raymond mill,HGM micro powder grinding mill,Ball mill, Jet mill,CLUM ultra fine vertical roller mill and so . Grinding Mill Sweden used ultra fine grinding mills in sweden. Ultrafine MillGrinding Equipment. It is the perfect ...

Secondary Grinding – Ball Mills In secondary ball milling, abrasive and corrosive conditions predominate. The smaller balls [< 2½", (65 mm)] typically used in secondary milling environments effectively reduce the impact component of wear to the point where grinding media must be primarily designed to reduce abrasive and corrosive wear.

Michigan Knife Co. (Simonds) Model 69 Motorized Sidehead Grinder. Michigan Knife Co. (Simonds) Model 69 Motorized Sidehead Grinder, S/N 855. Complete with ball bearing bed, 1HP, 115/230V, 1 Phase TEFC motor, steel factory floor stand, No. 2 taper spindle, and 9" maximum swing...

1 . mill ball Manufacturer:Jinan Zhongwei 2 . mill ball Usage:Abrasive Material for ball mill 3 . mill ball Diameter:20mm150mm 4 . Certificate:ISO9001:2008 As a leading global manufacturer of grinding media, ...

Description Used Continuous type Ball Mill of size 7 ft face length x 4 feet diameter x 1 inch shell thickness, drive having 60 hp 920 rpm slippring Kirlokar make electric motor and gear box, total connected power load is 85 hp. Mill is complete with the following accessories

This article on choosing milling media for a ball mill by Ned Gorski is a side article that goes with the "Ball Milling 101" Media Cautions. In his book Ball Milling Theory and Practice for the Amateur Pyrotechnician, Lloyd includes a section on casting your own lead media.

Maxicrom® grinding ball You can grind to the maximum with Maxicrom® grinder ball. It revolutionizes coarse grinding. It is used in the first chamber of raw grinding mills and cement tube mills. It leads the way in process efficiency and wears well with little deformation. Fewer topups will be needed which makes for less safety risks for ...

Grinding steel ball Forged and high Cr cast grinding ball for ball mill Grinding Steel Balls Chemical Elements( Below is common used type all over the world,if you have any other different requirement, please ... Read More. 14:29:30. 5565HRC Hardness forged steel grinding ball, ball .

Reliable and effective grinding mills includes being safe throughout. When the mills are quoted we make sure to include any and all safety components needed. Long life and minimum maintenance. To help you get the most of your business, we have designed our ball mills with longterm operation in mind with a minimum need for maintenance.

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

The industry best in energyefficient grinding, the OK Mill uses five to ten percent less power than other vertical roller mills and 30 to 50 percent less energy than conventional ball mills. Easy operation and maintenance. Worn roller grinding surfaces can either be replaced or rewelded inside the vertical roller mill.

6451 TransCanada Hwy Savona, BC V0K 2J0

Fineness Adjustable Cement Grinding Ball Mill Machine Used in Mining Industry_OKCHEM Please note that all emails sent by OKCHEM are from ***, servicemail., or notifications

GRINDING MILLSBALL MILLSPage 4New grinding mills ball mills. NEW AND USED BALL MILLS FOR SALE. Nelson Machinery supplies Ball Mills worldwide. We offer used ball mills as well as new, unused, and refurbished or rebuilt. We can also buy surplus ball mills or sell on a consignment basis. hydraulic cone jaw crusher saudis for sale in sweden

1 . mill ball Manufacturer:Jinan Zhongwei 2 . mill ball Usage:Abrasive Material for ball mill 3 . mill ball Diameter:20mm150mm 4 . Certificate:ISO9001:2008 As a leading global manufacturer of grinding .

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with .

Oct 26, 2018· Two types of grinding media are most commonly used: porcelain and metal balls. Porcelain balls are made of a pure white ceramic material that due to its vitrified body and high density, will not become damaged while in use. In recent years, their quality has improved immensely and they are now used exclusively in a number of industries.

Silicon Carbide Balls are very highcost grinding media that are used for milling same materials (silicon carbide ball to mill silicon carbide materials) to avoid contamination. They are only available in 5mm,10mm, 15mm and 20mm sizes. They are a special order item.

A VSI mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical shaft. This type of mill uses the same principle as a VSI crusher.. Tower mill. Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills .

WhatsApp)

WhatsApp)